The alarm was set for 4:00 AM. It was going to be a long day.

The mission was to travel to Haiti to survey space for a new community kitchen. The existing kitchen feeds some 1,400 children each day their only meal, which most days is no more than beans and rice. They are the lucky ones. Many children in the area receive only “mud cookies,” which is exactly what you are imagining.

Several Atlanta-area churches joined together to build a new, bigger kitchen in Port au Prince that can feed as many as 10,000 people. They enlisted the help of LandAir Surveying and Paul Gresham, an architect who works with Chick-fil-a and a member of one of the involved churches, to create a base map for the master construction plan.

I made the trip to Haiti with Allen Nobles, president of Nobles Consulting Group in Tallahassee, Florida. We have been friends for many years and have worked together on projects all over the country – but nothing quite like this.

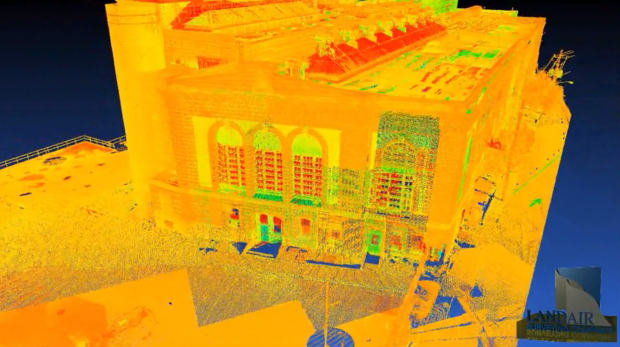

The plan was to scan the entire site consisting of an existing one-story school, an old building housing the existing kitchen, the future kitchen site, and a church and the campus walls around it. The existing kitchen has no running water and the sewer system is merely a pipe that goes through the wall to a creek out back. By Haitian standards, this is state of the art.

To further complicate matters, this is a particularly scary part of Port au Prince with a high crime rate. People are poor. Tourists have been kidnapped. Dysentery, yellow fever, malaria and cholera plague the area and the roads are full of potholes.

As we made our way through back roads crowded with cars and children, we finally arrived at the front gate of the school where the new kitchen will be built. Our van pulled into the tight driveway and the driver blew his horn, a sign for the guards to open the gate.

Once inside, we joined Paul, Pastor Vincent – the school’s headmaster – and a local architect assigned to help with the project.

Preparing to scan

Paul provided a general idea of what he needed for the design team. The school’s campus consists of a single story school building approximately 300-feet long divided into 10 classrooms. On one side of the campus is a large church that also serves as a meeting room.

In the center of the campus is a large building that is to be demolished. It houses a kitchen that is approximately 20-feet by 25-feet. The cooking equipment consists of some large bowls and pans used for both cooking and washing the dishes. The stove is simply six propane burners. This small kitchen serves 1,400 meals a day to the students and local children.

The goal was to produce a map of the campus and get enough information on the existing school so that a second floor could be added. Paul and his design team would prepare a master plan for future development, but their top priority was building a very large and modern kitchen capable of feeding 10,000 people daily.

When we decided to go on this trip, we knew we didn’t have a lot of time, so we built our equipment for lightness and mobility. It’s not easy to get all of the survey equipment you need into to backpacks and two small carry-on bags. You have to be creative and decide what you want, but take what you need.

Among that equipment was a Focus scanner and supporting equipment along with a small level, rulers, and a miniature tripod that folded up to 23-inches but expanded to about 65-inches. Allen also brought along some very handy paper targets with numbers and lead weights to hold them and a series of globes that cost around $5 each.

We had a two-minute project meeting with the architect and then taped-up 8-10 paper targets in the main area and started scanning with the Focus. Then we taped about 60 targets around the campus on the sides of the buildings, constantly moving the globes ahead of us and using the lead targets.

Once we had completed scanning the campus and buildings, we moved on to the roof.

View from the roof!

When you’re working inside the campus gates, you forget where you are. But when you are on the roof, it all comes back. Not 15-feet away, we could see a small alley filled with families and kids. Even though they were too poor to eat, they would look up at us and smile and laugh. They were very excited to see something different.

From the roof, there is also a clear view of the “river,” which is nothing more than the local sewer system run-off covered in garbage. Hogs, goats, and cows graze alongside it.

The trip also included a trek to New Life Children’s Home, an orphanage and oasis owned by a local woman named Miriam who had once found Pastor Vincent as a very small child, almost dead from starvation. She took him in and nurtured him back to health. He ended up going to college in Tennessee and returning to Haiti to start several schools and orphanages there.

The orphanage, which houses close to 100 children, has running water, bathrooms, electricity, clean bedrooms and many of the comforts of home. The electricity is run by generators and turned off at night to save energy.

After dinner, Paul asked us to look at a few of the buildings on campus to see if they could be scanned and documented. We did a quick assessment of what could be done given their tight timeframe and decided to scan one of the bigger, more complicated buildings first thing the next morning.

When all of the scans of the buildings and school were complete, Pastor Vince took us on a tour of the impoverished surrounding area known as Destiny Village.

I took a lot of pictures and some video on my iPhone, but after a while, you feel bad documenting the poverty surrounding you and realize how little they have, need or want.

What my household throws away in a week would feed two or three families.

Headed home

After clearing customs at the airport and heading back to Miami, Allen and I went our separate ways. But the 25 hours we spent in Haiti will stay with us forever.

I’m glad we were able to use scanning technology in Haiti as there is no better, faster or more precise way to document data. But the scanning was the easy part.

The hardest part was seeing how these people live and the difference between our lives and theirs. We know we can’t save all kids displaced by earthquakes, hurricanes, and dishonest dictators and government corruption in Haiti. But if the kitchen gets built and the kids get fed, we may have helped to save a few. That was worth 25 hours in Haiti.

Tate Jones and Allen Nobles have been friends in the surveying business since 2007. Tate is the president and owner of LandAir Surveying Company, based in Roswell, Georgia. Allen is president and owner of Nobles Consulting Group, based in Tallahassee, Florida. Together, they have worked on projects all over America and generally share resources and technical expertise. To learn more, visit www.landairsurveying.com and www.ncginc.com.

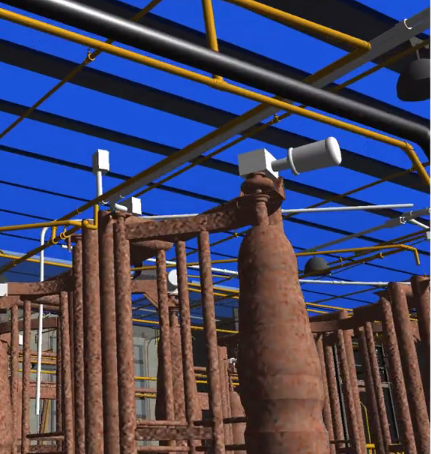

If you have recently considered using a survey company or are currently aligning with one, the term 3d laser mapping might have been mentioned. This process involves the use of a 3d laser scanner when surveying a structure or environment to capture extensive points of data about the area in a short amount of time. The scanner uses laser light technology to capture the data at a faster rate. 3d laser mapping offers greater efficiency over the traditional approach of visiting the building each time to take a measurement to know the actual dimensions.

If you have recently considered using a survey company or are currently aligning with one, the term 3d laser mapping might have been mentioned. This process involves the use of a 3d laser scanner when surveying a structure or environment to capture extensive points of data about the area in a short amount of time. The scanner uses laser light technology to capture the data at a faster rate. 3d laser mapping offers greater efficiency over the traditional approach of visiting the building each time to take a measurement to know the actual dimensions.