When we were asked to bring our booth and support the 2nd Annual Revit Technology Conference in Stone Mountain, Georgia, last week, I didn’t know what to expect. But I’m glad we went because we saw the future – and it’s very bright.

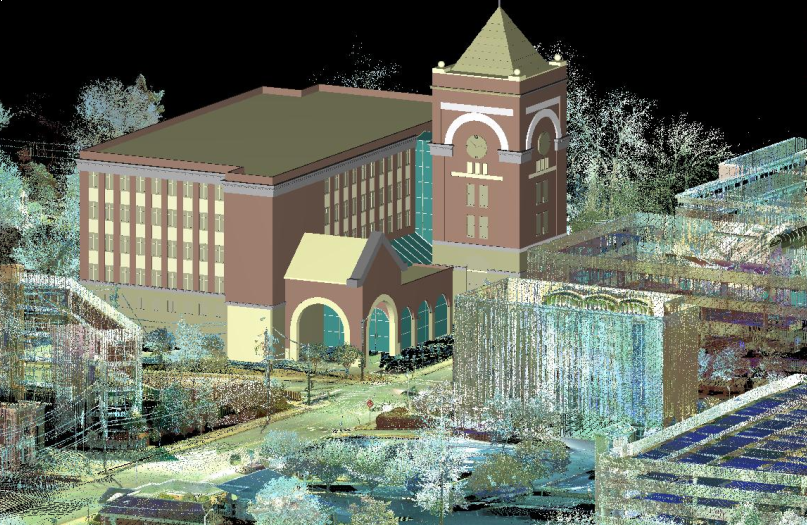

For BIM managers and designers, this conference was a look through the hourglass of the future at the world of design and one thing is for certain: gone are the days when firms could avoid BIM, 3D Cad modeling and laser scanning and still hope to be competitive. What I saw were bright young innovators already pushing the technology of 3D design and high speed data capture to the limits.

It was very refreshing to attend a conference where presenters and attendees agreed that 3D laser scanning was the best tool to use in many design situations and were openly discussing how they currently used the technology in innovative ways.

The largest 3D scanning show I attend every year is SPAR. I had the same feeling at the Revit Technology Conference last week that I had at the third SPAR show back in 2005 when laser scanning was still a new and relatively untested technology. The quality of what was being presented at the Revit conference – and how and who was presenting – was way up on the charts.

Around the showroom floor, there were the larger suppliers of the Revit technology, who were very knowledgeable about new improvements to the products, alongside many boutique firms that were selling all types of software to make the design process in Revit easier and more organized.

There were also other groups selling “cloud” technology that provided a new, more efficient vision of the cloud. While most of us already have data on our iPhones, it will be a short time before we will all have our data in the cloud and projects will be able to be worked on by anyone, anywhere with just a password and a computer.

On large mega-projects like new airports and major industrial facilities, multiple design teams in multiple cities will be able to work on the same cloud-based data at the same time. It will change the way we do things forever. Yes, there will still be security issues and priority issues, but ultimately that’s where we are headed.

Why have one computer process for one million seconds to solve a data set if you can have a million computers process for one second? It’s not quite that simple, but that’s the goal.

The speakers were great, too.

My favorite was Dick Morley. His opening presentation was in the form of a fireside chat with Brad Holtz serving as the interpreter. (I say interpreter because when the audience looked confused and a topic seemed to go over our heads, Brad would bring Dick back down to earth.)

Dick Morley invented the programmable logic controller, which pretty much controls all the electronic machinery in the world. To put it in prospective, that one device produces more revenue than all of Hollywood’s productions combined.

He also invented antilock braking technology, which revolutionized cars and greatly reduced accidents on the highway. (As a side note, he said that while the number of accidents decreased for many years, they slowly started going back up as drivers in America learned to drive closer using the antilock brakes. As the margin of error decreased, accidents increased.)

Dick also invented the cash register overlay that has pictures of food on it rather than numbers. This greatly reduced errors and increased production in the fast food industry.

Dick, who was trained in physics at MIT, had a clear message: “Look at where things are going and what needs to be solved and find the technology to solve it. Holding on to the way it has always been is just a reason to justify where you are – not a plan to move forward.”

I think this is true across the industry. The true leaders and innovators are not the ones who are really good at getting a piece of paper from the left side of their desks to the right, he said. The innovators ask, why paper?

Other interesting speakers shared new and innovative ways the power of 3D is being used across the spectrum. Kelly Cone with the Beck Group gave a very thorough presentation of using modeling in a major construction project and how the model was embraced and used by many of the subcontractors on the project.

They even built a “construction” roll-able computer workstation so the subs could walk over in real time, look at their section of the project in 3D, and understand the intent of the designer.

He also talked about how having access to quick laser scanning information helps designers and contractors come up with workarounds in tight spots.

The conference had attendees from most of the continents in the world and it was evident that critical mass has been reached and that the tipping point into 3D design technology is complete.

The transition away from 2D drawings and flat surveys is history and 3D models and clash detection and design testing prior to construction is now the new standard.

###

Tate Jones has over 40 years of experience in land and aerial surveying and was one of the country’s earliest adopters of 3D laser scanning technology. A nationally recognized expert in the field of 3D data capture, he has worked with hundreds of clients in the engineering, architectural and construction industries. Contact him at tjones@lasurveying.com, tjones@3DLaserSurveys.com or visit www.3DLaserSurveys.com.