In a few weeks, I am speaking at a conference about the future of laser scanning in the design and construction world.

The audience will be members of a top international construction firm that is very progressive in its use of BIM and 3D laser scanning, so it got me thinking about some of the research I have done and observations I’ve made at various 3D laser conferences over the last eight years.

Based on the incredible innovations in our field in the last decade, I have five predictions as to how high definition scanning will change design and construction in the near future:

#1: Rapid and creative increase in the use of the technology.

When GPS hit the market in 1992, we were early adopters of the technology and found great savings for our workflows as a result. For one, what used to take us two to three weeks of field surveying could now be done in just hours.

While there is still pushback in some sectors of the design industry related to laser scanning, contractors are largely on board. No other single group gets a better return on investment for the dollars spent on laser scanning.

Every major building contractor I know is using the technology in some way. The reason is simple. If something is designed from old plans and doesn’t fit, it is the contractors who will have to pay to make it fit. They live in the world of construction schedules and why is not nearly as important and when and how much!

The use of this technology will only increase in the future. Currently, 3D laser scanning technology is being used to show floor flatness with 3D contours well before the new floor is built. As a result, if there are any critical departures from the plans, they can be fixed for a fraction of the cost of what it would be once the walls are already in place.

BIM models are being compared to the laser scan in real-time so minor changes can be made before they turn into a major – and expensive – problem.

As we go forward, I see a time that scanners will be attached to each floor of a building as it goes up and will robotically scan at appropriate times, allowing the laser point cloud to be compared and clashed every night or even hourly to the BIM model to detect changes between the design and construction.

This technology has already reduced the cost of construction and will go upstream to reduce the cost of project insurance because it lowers risk.

#2: Video vs. Laser Scanning?

Ironically, one of the innovations of 3D laser scanning will be using the laser less and the iPhone more.

For many years, “close” range photography has been able to create accurate as built information. Used by experts who understand the survey control necessary and the techniques required, the results could be better than laser data.

Now there are firms writing software that can produce point clouds using video or multiple pictures of the same object (which is what video really is). With no control, it does not have the same accuracy as lasers, but the cost is significantly less.

There is a debate in the 3D world whether this will replace laser scanning or compliment it. I suspect the latter.

One study I read said that creating point clouds from photography currently was about 98% as accurate as a laser scan on smaller areas. That said, if you measured a room that was 100-feet long with a point cloud based on photography, it could theoretically give you a resulting measurement of only 98-feet long.

Consider this: How many times is 2% good enough? The truth is, many times it is. One of the oldest problems in scanning is how to get above the ceiling tiles to document the utilities above.

Getting a scanner up there is slow and expensive. Removing the tiles is slow, dirty and expensive. But if you could remove a few tiles and snap a few pictures, you could get an accurate inventory of what was there and where it was going that would be extremely helpful.

Much research is being done in this field, but I think in a very few years – depending on the specifications – we will be using cameras as often as lasers.

#3: Intelligent point clouds

This is where much of the research in software is going.

Right now, there are some programs that can model pipe correctly between 70% and 90% of the time. They can also recognize walls and show some, but not all, of the flat surfaces.

While this is a huge step forward, if only 80% are right then you have to check 100% to see which are wrong. You would not want to order a couple of hundred feet of the wrong size pipe and have in onsite only to find that it was the wrong diameter.

In the design world, it has always been our opinion that no data is much better than bad data. Ironically, the current software does have excellent object libraries, so you can isolate the point cloud of a structural I-beam and ask the software to find the right part and it does a great job. However, though it is a more reliable process, it is a manual process.

I believe this problem will be completely solved in less than two years and the use of point clouds will increase exponentially.

#4: Why create a model at all?

At the risk of creating total confusion, there is a growing group of expert users that ask this very question, why model at all? Their thinking is that when you model, you change the shape of the object scanned and the cleaned point cloud is a better representation of an object.

That being said, with the ability to bring the point cloud into design programs, more professions – especially the high precision users – are designing inside the point cloud and not from a model.

I saw a fascinating presentation by a satellite designer. When another payload was added to the satellite, he would not work off the plans, but instead scan the existing satellite in the next room and use that point cloud for the additional design. Of course, we don’t all have the luxury of having a working copy of the design next door.

The important point here is that for critical design, the point cloud is closer to reality than the model. The other realization is that nothing is ever built exactly as it was designed.

#5: Advanced data capture platforms

This will be one of the biggest changes and most fun to watch.

Currently, we use helicopters, fixed-wing aircraft, automobiles, trucks, off road vehicles, boats, and tripod-based systems to collect data. Though these work well for most uses, many of the projects that need scanning are in dangerous conditions. (Tunnels, large underground pipes, underground mines, failed construction areas, high voltage transformer stations and nuclear power plants.)

All of these areas have one thing in common: they are unsafe.

Enter drones and walking robots. When the nuclear power plant in Fukushima, Japan, failed and melted down, the level of radiation was so high that the workers could spend very little time inside the radiation zone.

The team brought in a small drone that delivered high quality close range aerial photography and was equipped with avoidance technology so it would not fly into a fixed object. The digital information was extremely valuable in assessing the damage and did so safely with little human risk.

I have already seen experimental drones equipped with small scanners that are programmed to scan flat surfaces and recognize open areas like doors. They will go through to continue the scanning in areas that, because of gas or other dangers, would be very difficult for humans to work in. In studying the decaying infrastructure of America for rehabilitation, can you imagine being able to put a drone down the sewer systems of New York City or Atlanta and get high resolution scan data without having to put people in such an environment?

Track mounted robots are being used in the same way. These will definitely be used more and more in the future and will change the way we work.

The future of scanning is immense and the different ways we scan – the data capture vehicles and the software – will continue to evolve and become more customized to the specific industry problems presented. Point cloud data, whether collected with lasers or iPhones, is still the best data that exists for capturing and studying existing conditions.

The future will be exciting to watch and the prize goes to the person or company that can best see beneath dense foliage, behind walls, or under the ground.

###

Tate Jones has over 40 years of experience in land and aerial surveying and was one of the country’s earliest adopters of 3D laser scanning technology. A nationally recognized expert in the field of 3D data capture, he has worked with hundreds of clients in the engineering, architectural and construction industries. Contact him at tjones@lasurveying.com or visit www.landairsurveying.com.

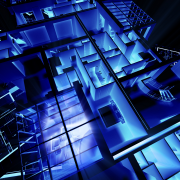

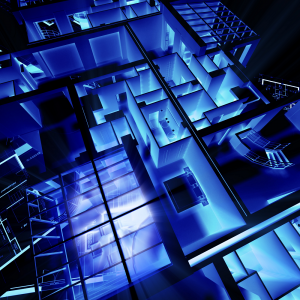

Many beneficial technologies have emerged to aid in processes such as surveying, architectural design, and land or property evaluation. Among these options, 3D Laser Scanning Technology is used in several ways to help with the design and construction of buildings as well as for gaining survey information about a location. 3D Laser Scanning Technology makes it possible to provide real, life-like images of a piece of land, location, or existing building to make well-informed calculations and designs.

Many beneficial technologies have emerged to aid in processes such as surveying, architectural design, and land or property evaluation. Among these options, 3D Laser Scanning Technology is used in several ways to help with the design and construction of buildings as well as for gaining survey information about a location. 3D Laser Scanning Technology makes it possible to provide real, life-like images of a piece of land, location, or existing building to make well-informed calculations and designs.