As a facility, hospitals and other healthcare buildings present a unique situation.

They have the aesthetic needs of a hotel or retail store, but the engineering requirements of an industrial or mechanical facility. These competing needs make space allocation difficult for design, construction, and operations and when renovations are due, accurate as-built information is absolutely critical.

3D laser scanning delivers perfect as-built information to meet the MEP and architectural needs of even the most complicated facilities.

Changes are always afoot in hospitals

Hospitals facilities are anything but static. Improvements in technology constantly call for new equipment and can shrink or modify the size of existing equipment.

Equipment and mechanical rooms in hospitals are notoriously crowded. Walls, ceilings, kiosks, laboratories, and operating rooms are virtually full of pipes, wires, conduits, and other tools of the MEP (mechanical, electrical, and plumbing) world.

This makes renovations difficult for both design and construction.

There is a human factor, too. Office layouts change as employees are churned (or “moved” in facilities management terms). Departments often have to compete for space and square footage comes at a premium!

The health and safety of employees is also a consideration. Hospitals must comply with statutory requirements related to office layouts including the minimum amount of space per employee, security features, fire safety protocol, ventilation, temperature control, restrooms, dining facilities and more.

3D Laser Scanning: Perfect asbuilt information

3D laser scanning allows architects and engineers to design renovations from perfect as-built information. This directly addresses the need for accuracy within the tight tolerances of the hospital environment. Since human measurement error is eliminated, re-designs are greatly reduced and errors and omissions on the construction and architectural plans are also of no consequence.

3D laser scanning also gives contractors the upper hand. Since designs are based on actual existing conditions, the contractor can be more confident that it is constructible as designed. Plus, precise material schedules developed from the model help avoid cost overruns.

The contractor can also use “clash detection” to determine exactly what must be moved or removed to complete the renovation. This technique compares the scanned as-built world to the construction plans and shows which areas are trying to occupy the same space. This significantly reduces change orders.

Owners and facilities managers also save money through efficient design and construction, as they can use the 3D picture of existing site conditions as a decision-making and communication tool during construction and a facilities management tool afterwards.

How it works

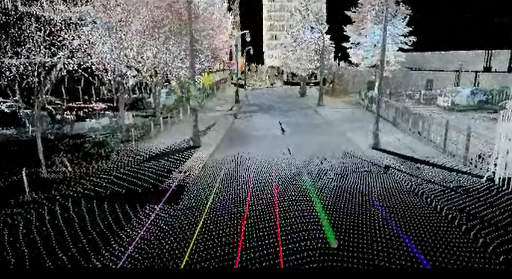

A 3D laser scanner uses harmless light rays to collect the 3D location of every object and surface it can “see” from where the instrument is set up. Scanners automatically rotate 360 degrees on a tripod, sending and receiving these light rays in all directions. In about five minutes, the scanner setup is complete and millions of data points have been collected.

This data, which is known as a “point cloud,” is a perfect 3D asbuilt of existing conditions. The point cloud can be used by itself or modeled in a software program.

Advantages over traditional as-built techniques

3D laser scanning has many advantages over traditional measuring techniques including:

- Accessibility: 3D laser scanners collect information from areas that can be seen but not easily accessed. For instance, scanners can collect information about MEP pipes and wires running along ceilings and other inaccessible areas.

- Speed: Each scanner setup takes less than five minutes, so scanning crews can be in and out of an area quickly, without disturbing patients and without compromising the integrity of the data.

- Safety: Since the scanners use harmless light rays to take measurements, neither patients nor field crews are affected. In fact, field crews do not have to be in a place to measure it.

- Detail: No other data collection system records such precise information. Architects can see finishes, molding, and other aesthetic features and engineers can measure the locations of all objects seen by the scanner.

Conclusion

The strengths and efficiencies of 3D laser scanning are extraordinarily applicable to the unique environment of healthcare facilities. From design through construction and facilities management, all parties benefit from the precise as-built information given by this remarkable technology.

###

David Headrick has over 20 years of experience in the surveying, engineering, and legal industries, both as a project manager for LandAir Surveying and as a lawyer in private practice. He has represented numerous land surveyors, designers, architects, contractors, and other industry professionals throughout his career. Today, David serves as an executive and project manager for LandAir Surveying Company, Inc., focused on developing and managing the company’s 3D Laser Scanning Division. Contact him at (865) 599-0148 or dheadrick@lasurveying.com.To view his LinkedIn profile, click here.