What’s all the fuss about high definition scanning?

When it comes to making precise measurements in complicated environments, high definition scanning – or 3D laser surveying, as it is sometimes called – is quickly making its way to the front of the line in a wide range of industries from engineering to historic preservation.

Engineers use laser scans to work with real-world conditions in complex industrial as-built and plant environments. Construction companies use them to gather precise data on site terrain and renovations, and architects use them to check proposed design models against existing conditions to fine-tune their designs.

Even insurance companies and law enforcement have gotten on board, utilizing the technology to recreate large-scale accident scenes.

Why is it better? For one, laser scans are incredibly precise. Images are created from a “point cloud” of millions of points that can be measured precisely including the distances and elevations between points. They are also versatile. The scans, when used with digital color photos, can produce survey-quality files, videos or even 3D animated computer models and are so intuitive that even a novice can understand the information.

Laser scans are also fast. In 2006, when we bought our first scanner, it took almost an hour to produce a full dome 360 degree scan. Now we can scan in 6-8 minutes. This allows us to take many more scans and capture more detail than we did before.

Scanning almost always pays for itself. It is cheaper in the long run because you can revisit the original scan multiple times from your computer desktop without having to revisit the project site. Also, because the technology is so precise, the need for construction reworks and expensive retrofitting is minimized or removed alltogether.

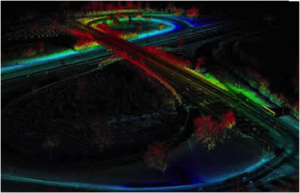

For firms thinking about getting involved with this technology, there are currently three ways to capture 3D data on large scale projects: Airborne LiDAR (Light Detection And Ranging), Mobile LiDAR, and Terrestrial Scanners, which all produce LiDAR data.

Typical projects for terrestrial scanners are large pipes and tunnels, manufacturing facilities, plant process facilities, airport conveyor systems, bridges, buildings, towers and construction projects. (Our firm focuses on terrestrial jobs, as most cannot be readily scanned from airplanes or cars.)

The cost of entry into this kind of scanning is generally between $150,000 to $250,000 for the first units and software. (Although less expensive scanners are now available, software packages can still be expensive and the cost of training should also be considered.)

Aerial platforms and Mobile Platforms start at $500,000 and go up to $5,000,000. These units are constantly being upgraded with newer and better digital sensors and data management enhancements. We currently work with service contractors on these types of jobs, which are typically focused on documenting civil infrastructure on a much larger scale than terrestrial scans.

Projects could include scanning 100 miles of road to prepare a pavement analysis, mapping 1,000 miles of rail line, or mapping the City of Atlanta and producing 3D models of all the buildings.

If the cost of these units seems intimidating, keep in mind that firms that have already invested in these technologies are often open to partnering opportunities with smaller firms.

Small scanning focuses on objects the size of a Volkswagen all the way down to the mechanical components inside of a watch. The applications in this field – commonly referred to as “reverse engineering” – include quality control of manufactured parts or data capture for a manufactured process. A typical project could be scanning an ornate stair rail so that an exact replica can be created from wood, metal or composite.

This scanning method is so precise that you could dissemble a toaster, rifle or carburetor, scan the parts, manufacture duplicates, and they would all work when re-assembled.

What can be scanned?

If it can be built, it can be scanned. There is virtually nothing built that cannot be duplicated and modeled with current scanning techniques.

In addition to the engineering, construction and manufacturing industries, this technology is also being used by insurance companies and law enforcement to reconstruct accident scenes – like when a highway bridge falls during rush-hour traffic or a multi-car pile-up – and even on Hollywood sets. There are companies that make their living scanning elaborate movie sets before and after they are constructed.

To give you an idea of the wide-ranging capabilities of this technology, in the last month, we have scanned a 120-foot pipe in Chicago, a 737 aircraft in Delaware, a luggage system in LaGuardia, and the interior of a peppermill in Virginia. This technology is everywhere!

###

Tate Jones has over 40 years of experience in land and aerial surveying and was one of the country’s earliest adopters of 3D laser scanning technology. A nationally recognized expert in the field of 3D data capture, he has worked with hundreds of clients in the engineering, architectural and construction industries. Contact him at tjones@3DLaserSurveys.com or visit www.3DLaserSurveys.com.