BIM: Breakfast of Champions

Whenever my travel and work schedules allow, I try to attend the BIM Breakfasts at Georgia Tech.

Held once a month on the Georgia Tech campus, the breakfast brings together some of the best and brightest minds in the Atlanta area.

The February event featured speaker James Barrett, the national director of integrated building solutions for Turner Construction. Jim specializes in virtual design and construction/Building Information Modeling (BIM) technologies, lean processes, and integrated project delivery.

Put in layman’s terms, he is pushing BIM and virtual design tools to the limit. Under his leadership, Turner Construction has become one of the top BIM users in the world.

Jim does not push BIM just because it’s BIM. His idea is that his designers and contractors need to use the best tools available to help their company succeed and their clients get the best results. The BIM process and virtual design flows naturally from that core idea.

Turner also does not push one specific type of software, but instead teaches as many as 10 or 12 different packages that their best and brightest have become familiar with. As with any tool, Jim explains, no one tool will do everything.

Another point he made was this: when you roll out a new technology, don’t try to convince the world that it’s the best way to go. Instead, show it to the early adopters and let them prove that it works and that it’s the most efficient option. It will naturally make its way to other potential users.

For me, this point really hit home.

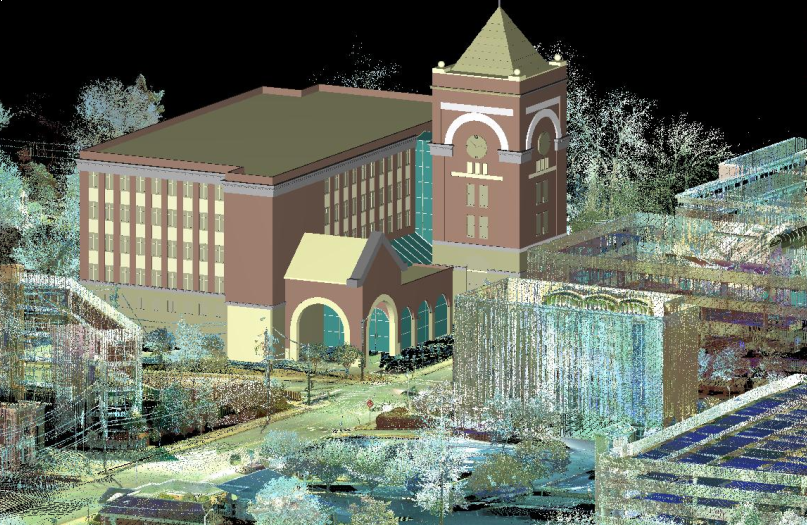

In 2005, we began using terrestrial lidar and 3D scanning technology. I have traveled to many firms in the southeast and tried to sell the benefits to the whole AEC community.

Initially, I had minimum success. It was early in the process and few of the established firms were interested at that time. However, I did find a few and slowly built a successful 3D laser scanning division that still thrives today.

These firms were the early adopters. Ironically, it was not always the young guys that were the most open to new ideas. Sometimes it was an older person who could see like I did where this technology was headed.

Now this technology is almost mainstream and is an integral part of the BIM process.

In his presentation, Jim pointed out that in New York City they have “view protection” and laser scans are used to document the view of the construction site.

In the BIM toolbox, when you identify a complicated project, laser scanning is a tool that you should certainly consider. The benefits and uses of laser scanning data are numerous and the risk of not using one and incurring additional costs down the road can be significant.

Another really good idea that Jim presented was that every year, they take a small percentage of their new hires and immerse them into what they call BIM University.

These people then become experts that the rest of the company can learn from. This gives every group in the company and geographic area internal experts that they can lean on to best implement the technologies of BIM. What a great idea!

They even started an intra-company communication site on their intranet so that users anywhere in the company can post a question. In minutes, experts throughout the company can provide insights and answers and have a forum to share their knowledge.

I believe this practice will continue to grow as companies see the value of tapping into the knowledge base they already have with their employees. What a great tool for a leader to build in their own company.

Jim’s presentation also touched on the other tools that help to automate the construction and design process like the ability to view augmented reality on iPads with the use of QR codes. At his firm, they work with public inspectors to load iPads with plans and drawings to make their process quicker and more efficient.

He also addressed the effect that 3D printing will have on the construction industry. Though it will not likely take the place of massive building material needs, it will fill a unique need when a limited number of items are needed in a quantity that can be met with industrial 3D printers, he said.

There will always be people who question whether we need BIM and virtual design and construction. I cannot completely understand why anyone in the AEC industry would still be asking this question, but I do understand that in some subsets, there is much more low-hanging fruit than in others and for these, early adoption is a no brainer.

The push for BIM and virtual design use and innovation is coming out of the construction industry as the large GC firms have pushed it further and further into their processes.

If you are in the Atlanta area and want to see and meet some of the best minds in BIM, I do recommend the Georgia Tech BIM Breakfast forum. Every time I go, I learn something.

###

Tate Jones has over 40 years of experience in land and aerial surveying and was one of the country’s earliest adopters of 3D laser scanning technology. A nationally recognized expert in the field of 3D data capture, he has worked with hundreds of clients in the engineering, architectural and construction industries. Contact him at tjones@lasurveying.com or visit www.landairsurveying.com.