The field scanning process: How to get the best results

Once your laser scan has been ordered, there are some things you can do to prepare for our crews.

First, prior to the scan, have someone (preferably a knowledgeable project manager) onsite to communicate with the scan team when they arrive.

Make sure your plant managers know crews are coming. If there is a local safety course that needs to completed or specific plant instructions, let them know upfront. Also let crews know if there is special gear they may need like moon suits, hairnets, safety glasses or ear protection.

The project walk-through is a very valuable process because this is where we determine the location of the scanner setups. Let crews know what is most important and what is less important. If a major conduit with fiber optics, a power transmission conduit, or particular piece of machinery is important to your project, for example, it is important to let the scanning crew know.

Also make sure the scanning crew has a contact that they can call if they have questions or need clarification mid-scan.

Crews will place targets around the scan area to tie all of the scans together and will remove them upon completion of the site visit. Once they understand the limits and the prime areas of interest, the scanning process will begin.

Though it is great to watch them work, these teams are professional and the less direction they have, the better the results! A typical job can take two days to several weeks. Each night, scanned data for the day will be checked to make sure there are no gaps or geometric issues with the data.

For black and white scan data, the process is simply this: scan, move to a new location, scan, move to a new location, etc. For color data, a set of photographs is added to the process: scan, remove the scanner, add a camera, take seven photographs (six at 60-degrees horizontally, one straight up), move the scanner, take photos at the new location, replace the camera with the scanner, scan, and repeat this sequence throughout the site.

This allows our crews to produce high-quality TrueView files. When they get into a rhythm, the above sequence maximizes efficiency up to 100%.

Post Processing

When the scan data comes back into the office, data is exported from the crew’s field laptop to the desktop. On large jobs, this will take several hours.

Next, if there are color photos, the color photo data is downloaded and registered to the point cloud. This process can take 5-10 minutes per set up. Around 100 set-ups can take 15 hours of technician time. (If there is only black & white data, we skip this step.)

Once the photo data is added to the raw data, the target information is then added to the data set. The data is then run through the final registration process. This program compares the data set to all the other common data sets and produces the final registered point cloud.

The point cloud is then tested visually and geometrically to make sure there are no errors. This is done by cutting it like a wedding cake to see that all of the horizontal surfaces line up and also looking at elevation views and pipe runs to make sure that these are consistent throughout the cloud.

After these are tested, the final registered point cloud is ready to be used. Files are then loaded on to a hard drive and shipped to you, the customer!

Now that you have the point cloud data, what do you do with it?

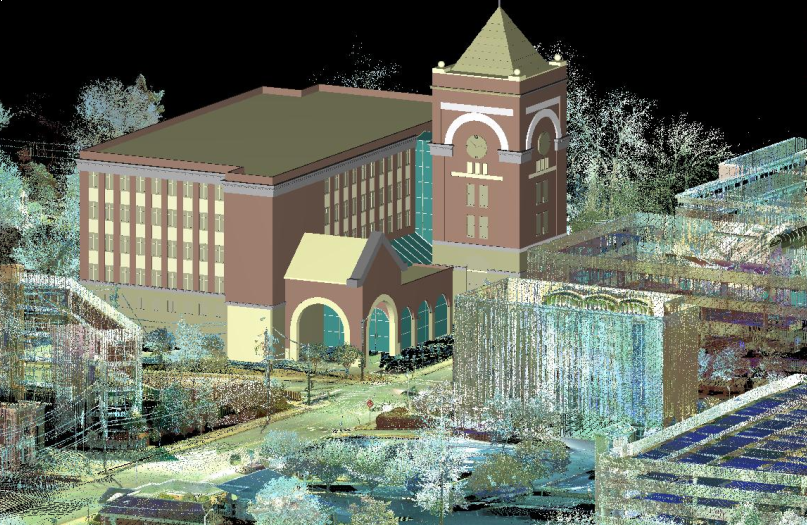

Registered point cloud data can be exported into AutoCAD, MicroStation, Bentley, Revit, Autodesk Recap and many other computer programs. Designers can then take this data and design and model it in a 3D environment.

A TrueView map of the site showing 3D spherical data in black & white or color can be created. You can measure between points in the point cloud with this free program.

Warning: We always recommend that for precise measurements, you use the point cloud information and not TrueView. The angle of the view can affect the measured distance in TrueView. At a minimum, check the measurement from several different views.

Computer models can also be built in Revit, AutoCAD or MicroStation and delivered to the client. These models can be imported into the point cloud and then “clashed” to see if the new model interferes with the existing point cloud.

Want to learn more? Contact us today to learn if a laser scan is right for your next project.

###

Tate Jones has over 40 years of experience in land and aerial surveying and was one of the country’s earliest adopters of 3D laser scanning technology. A nationally recognized expert in the field of 3D data capture, he has worked with hundreds of clients in the engineering, architectural and construction industries. Contact him at tjones@lasurveying.com or visit www.landairsurveying.com.