Autodesk University 2012: watching an industry grow up!

Attending and exhibiting at shows like Hexagon, Spar, and Autodesk University is always fascinating because you get to interact with clients all over the country and see what’s new in the industry.

This was our first time exhibiting at Autodesk University, but having been to three conferences in Las Vegas in one year, I was quite familiar with the surroundings. At this year’s show – which was attended by over 8,000 people from 102 countries – what I saw was an industry that has grown up and is beginning to make a real impact on design and construction.

I remember in 1986 when a new drafting program named AutoCad came out and everybody was debating if it would become the standard…it did. And it brought with it – along with the digital age and computers – the plotters and all that went with the introduction of this new paradigm.

Most of us waited to see how it would be received in the industry, but then – as now – it proved to be a very valuable tool.

And just a few years ago, we were all still discussing the advances in AutoCAD and Civil 3D. Though we knew these programs would remain relevant, it was evident from all of the different software that interacted inside of Revit and enhanced the user experience that the world of 3D design was here to stay. (As a friend of mine said not long ago, “If you are not designing and interacting in 3D and models, you are quickly going to be obsolete.”)

Autodesk University 2012 showed us how design is being done today and where it is going in the future. One of the more interesting observations was that besides the architects, engineers and designers, there were contracting companies, retail companies and owners all talking about the new Autodesk programs that were being used in the workplace.

There was lots of talk in these groups about building “Revit families” specific to their business types, as well as discussions around how to mix the contractors (who have the knowledge about how a building is built in the actual world) with the BIM modelers so that the models are also constructible.

This will be a big challenge. Contractors and superintendents who know how to pour a slab and build 20-story buildings have knowledge and insight that is absolutely critical to building a proper BIM model.

As any techno geek, I am always very interested in the new products on the exhibition floor and the showcase included hundreds of third-party vendors developing exciting products that work alongside Autodesk.

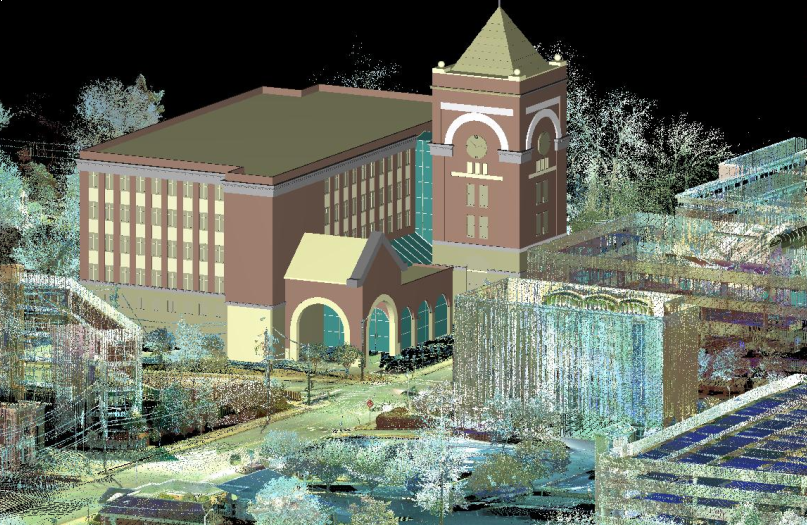

There were lots of new software and hardware lines in the 3D laser scanning industry, as well as new software offerings for BIM models, Revit technologies and GIS products. But for me, the most intriguing products were related to 3D printing applications.

These fabrication and modeling solutions enable products to be created directly from their computer models.

Almost anything you could imagine – from cars to motors to guitars – was printed and on display. Though 3D printing has been a popular topic in recent years, it was there, it was real, and it will definitely change how items are built in America and around the world.

At the conference in Vegas, there were actual printers producing objects out of wood, metal and polymers. The only difference was whether the printer was loaded with plywood or metal.

BIM is an acronym for Build Information Models, meaning to build computer models that have built-in intelligence. What I observed was BIM in the context above – building models and objects with just the information in a computer.

My, how we have grown.

###

Tate Jones has over 40 years of experience in land and aerial surveying and was one of the country’s earliest adopters of 3D laser scanning technology. A nationally recognized expert in the field of 3D data capture, he has worked with hundreds of clients in the engineering, architectural and construction industries. Contact him at tjones@lasurveying.com or visit www.landairsurveying.com.