Laser Technology Makes Traditional Field Measuring of As-Builts Obsolete

Ask architects what they dislike most about their jobs and many will agree that taking field measurements ranks pretty high.

Measuring as-built conditions takes architects out of the office and away from the work they enjoy most and what makes them money. And many times, traditional measuring methods are inaccurate and time consuming – and that’s when the environment is simple!

When there are difficult conditions, taking measurements can be next to impossible. And not to mention, inevitably, there is always something missed or the field notes don’t quite match up to the rough sketches done onsite.

Today, there is a better answer to field measuring existing conditions in the form of laser technology.

LandAir Surveying utilizes 3D laser scanning and laser measuring technologies to provide a modern solution to the task of field measuring as-built conditions. Depending on the level of complexity, amount of detail needed, deliverables required and timeframe, we can dictate which laser technology is right for each individual project.

The power of laser scanning

Laser scanning is the surveying technology of choice when it comes to difficult environments. Historic buildings, exterior elevations, heavy MEP conditions and the need for very precise measurement data capture are all examples of when laser scanning technology should be used.

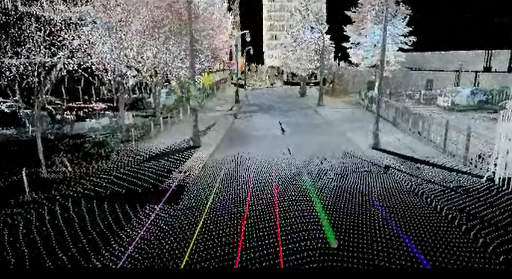

Laser scanning generates millions of data points to create a 3D image referred to as a “point cloud.” The point cloud can be measured and viewed in any direction, which virtually puts you back at the work site.

The point cloud is then utilized to generate AutoCAD drawings, building information models (BIM), or used as a design tool itself.

The speed of laser measuring

Our advanced laser measuring technology allows for exact measurements and real time data capture of critical data and building geometry. The use of wireless laser range finders and a remote BIM workstation reduces data collection time, increases accuracy and eliminates rework.

Models and AutoCAD files can be generated onsite and in real time, as well as quality control and field verification, which greatly reduces the amount of work required back in the office.

Here are just a few examples of how laser scanning and measuring have provided more accurate information while saving valuable time and resources in the field:

Project Case Study: Historic Hotel Renovation

A historic hotel built in the 1930’s with no existing documents and in a bad state of disrepair was scheduled to be renovated into a modern boutique hotel.

LandAir utilized both 3D laser scanning and laser measuring technology to provide a point cloud, TruView, fly-through video and AutoCAD drawings. Laser scans were performed on the exterior of the hotel to provide elevation drawings.

The eight-story hotel’s exterior was brick and adorned with many architectural details. The laser scan was able to capture all of the exterior data measurements and provide additional helpful details that were viewed in the point cloud including sidewalks, tree clearances and parking lot details.

The laser scan was continued into the lobby and through the first floor of the hotel, helping tie together the laser scan information and laser measuring software. Due to the nature of the construction of the hotel, each one of the over 140 rooms had to be individually measured and floor plan documents created.

With LandAir’s workflow design and remote BIM workstation, QA/QC was able to be done on the rooms in the field and the irregularly shaped rooms were verified on site.

Project Case Study: Big Box Retail Conversion

A grocery store and two adjacent in-line stores had gone dark and were going to be renovated to accommodate a new tenant. The option on the building was expiring and there were no existing documents to help determine if the space would work for the future tenant.

LandAir utilized laser measuring technology to provide AutoCAD documents and a 3D model to the designer and tenant in less than two days. The proposed design and tenant requirements were compared to existing conditions and the project was able to move forward in the required timeframe.

Project Case Study: Pedestrian Bridge Addition

A pedestrian bridge was proposed to be built over an extremely busy street in a large Metropolitan downtown connecting a hotel and parking deck. No drawings were available and the proposed bridge was four stories above the street, making traditional measuring very difficult and dangerous.

LandAir conducted a 3D laser scan of the exterior of the hotel and the existing parking deck. The street scape conditions, power lines, traffic signals and building tie-in points were all measured accurately and safely from the laser scanner.

AutoCAD drawings, a TruView and a video fly-through were provided for the project team. The point cloud fly-through provided a 3D visualization from any vantage point of the proposed bridge.

This helped the hotel determine how the sight views of rooms would be affected and allowed for inspectors, DOT officials and the downtown development authority to understand the impact of the proposed bridge.

Project Case Study: Mall and Food Court Renovation

A three-story open atrium food court was to be redesigned and new tenants added to the mix.

The existing documents were not a true representation of existing conditions as, over the years, there had been changes and alterations to the space. Additionally, the height and design of the atrium had many features that were difficult to measure.

LandAir laser scanned the atrium and surrounding spaces to provide a 3D model and clash detection for the proposed design changes. Laser measuring was also utilized to produce exact as-built documents for the surrounding spaces so that the mall owner could provide drawings for future tenants to build out their stores.

Each project has its own challenges and needs. LandAir uses the latest laser technologies to improve these projects and put an end to one of the most painstaking tasks in construction: field measuring. Are you planning to attend ICSC RECon 2013 in Las Vegas next month? If so, e-mail me at mdorsett@lasurveying.com. We would love to meet you there!

###

Mitch Dorsett has over 15 years in the building and construction industry and serves as director of business development for LandAir Surveying. Mitch is rapidly becoming an expert in 3D data capture and virtual design and construction, having attended and represented LandAir’s laser scanning capabilities at SPAR, RTC and Autodesk University in 2012. Contact him at mdorsett@lasurveying.com or visit www.landairsurveying.com